R&D Activities

Inorganic Chemicals Division

ISK takes on the challenge of achieving technological innovation that will lead to the creation of a sustainable society.

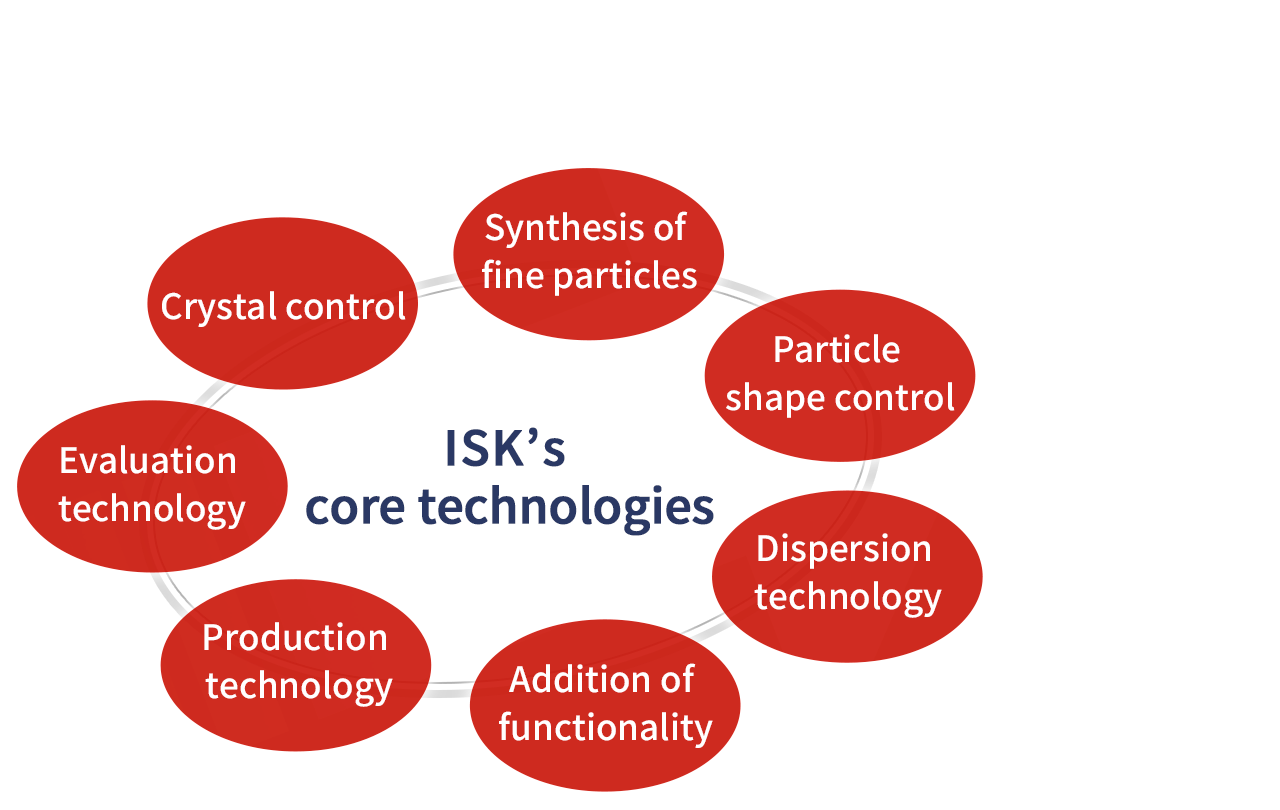

ISK has proprietary technology which it developed through the production of titanium dioxide pigments. Leveraging this technology and developing and introducing innovative techniques, we promote the development of products and processes that support the environment and information society and help build a sustainable society.

Strengths

-

Strength 1High in-house technical expertise

-

Strength 2Taking on challenges to develop new technology

-

Strength 3Providing materials precisely meeting customer needs

Research Description

Product development

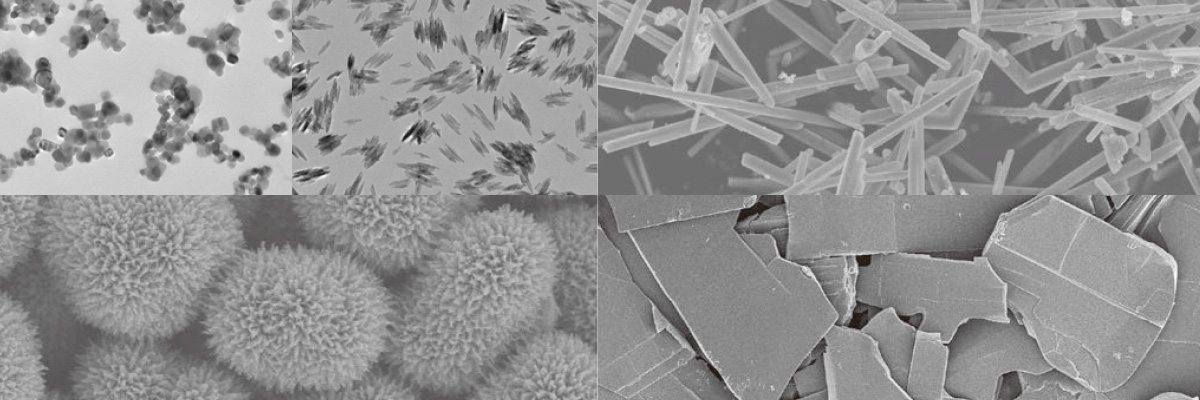

ISK’s particle shape control technology

ISK’s particle shape control technologyWe develop titanium dioxide and other coloring materials as well as functional material products such as high-purity titanium dioxide and conductive materials. In the field of coloring material development, we focus on developing new coloring materials such as layered titanate and black heat shielding materials (e.g. bismuth sulfide).

Missions

-

Mission 1Overcome challenges for technological innovation.

[Creation of new materials on a regular basis]

[Development of ESG-minded products] -

Mission 2Expand the line of high-performance and high-value-added products.

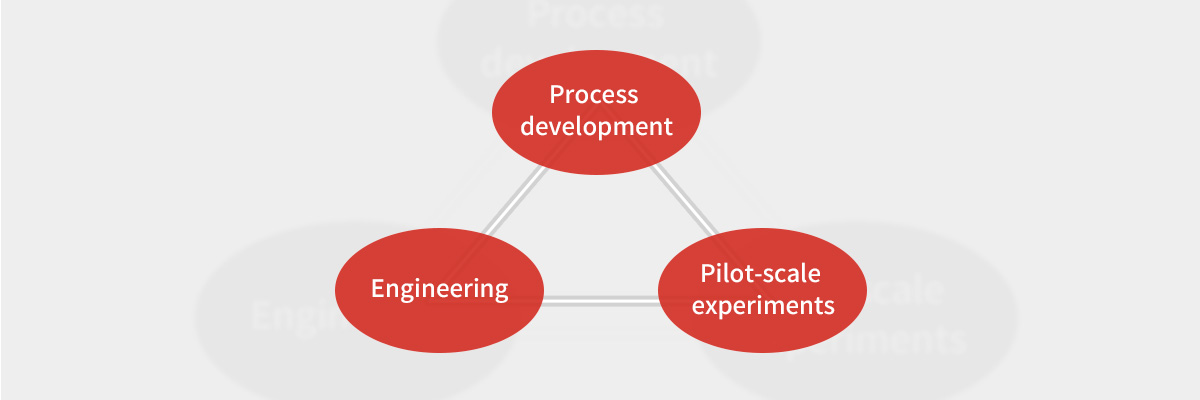

Production technology

Missions

-

Mission 1Improve productivity and quality.

-

Mission 2Explore the introduction of new equipment, develop new manufacturing processes, and consider scaling them up.

-

Mission 3Improve productivity, quality, and safety at the Yokkaichi Plant.

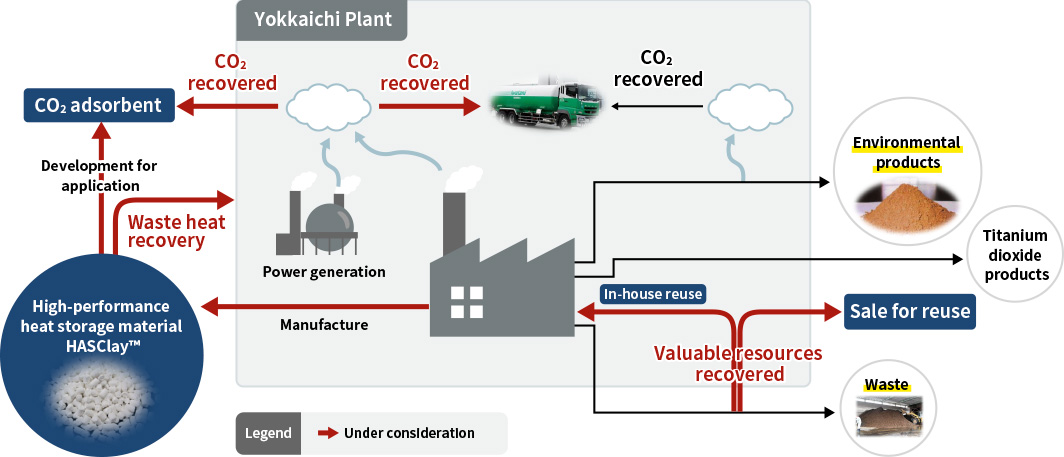

Technology development that helps achieve SDGs

We aim to establish technologies geared for a recycling-oriented society, using open innovation in addition to our core technologies.

(Examples of initiatives)

As part of our technology development that will facilitate sustainable production activities, we are working to reduce waste generated at our production plants, collect and reuse valuable materials, and collect and reuse CO2 exhaust gas.

Moreover, in the field of heat recovery, we will supply high-performance heat storage materials that are helpful for systems that efficiently utilize waste heat generated at power generation facilities and factory facilities in various situations such as drying, air conditioning, and food cultivation.

*You can see the entire image in the figure by scrolling horizontally.