Functional Materials

Ultrafine Particle Size Titanium Dioxide

Fine particles of titanium dioxide synthesized in the nanometer range achieve excellent UV protection and high transparency.

Strengths

-

Strength 1Highly stable fine particles of R-type titanium dioxide

-

Strength 2Refining technology used to process the raw material TiCl4 ensures a low heavy metal content (low As, low Pb), making the product safe for use in cosmetic applications.

-

Strength 3You can choose the most suitable product according to your varying needs from a complete line of products (calcinated, wet-processed, hydrophilic, or hydrophobic).

-

Strength 4We deliver products of stable quality using manufacturing technology that we have developed over many years.

Typical Applications

- Cosmetics

- Automotive paints

- Base film layer material (magnetic recording tape)

- Catalyst carrier

- Toner additives

Characteristics of TTO series

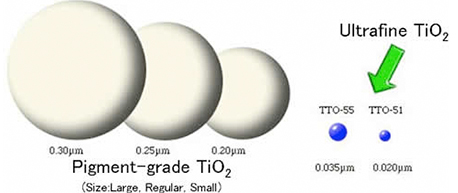

- TTO series are ultra-fine TiO2 products whose particle size is below 100nm.

- TTO series can achieve excellent transparency and UV-shielding capability. (Click here for transparency of TTO series.)

- When applying for metallic paints, viewing color is varied due to the light scattering ability which is characteristics of ultra-fine TTO. (Click here for flip-flop effects.)

- Physically and chemically stable due to the rutile crystal.

- Various grades are available depending on the particle size, manufacturing methods and surface treatment.

Comparison of particle size

General relationship between the primary particle size and UV-shielding capability

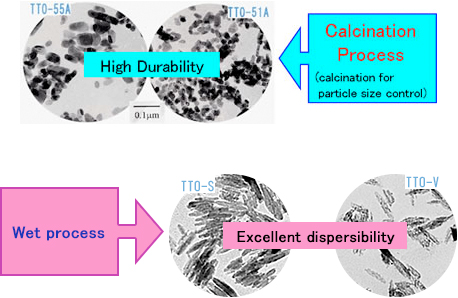

Classification by manufacturing method and particle size

| Particle size | Calcination process | Wet process |

|---|---|---|

| Large | TTO-80 (A) MPT-142 MPT-140, MPT-141 (newly developed) |

|

| Medium-sized | TTO-55 series | |

| Small | TTO-51 series | TTO-S series MPT-136, MPT-186 MPT-187 (newly developed) |

| Very small | TTO-V series |

TTO grade lists

1. TTO-51,55 series (Calcination process)

The TTO-51 and -55 are standard grades of the TTO series. They are available in a variety of products with features such as transparency, UV-shielding properties, and weather resistance.

*You can see the entire image in the figure by scrolling horizontally.

| TTO-51(A) | TTO-51(C) | TTO-55(A) | TTO-55(B) | TTO-55(C) | TTO-55(D) | |

|---|---|---|---|---|---|---|

| Crystal form | Rutile | |||||

| TiO2(%) | 76-83 | 79-85 | 93-98 | 88-94 | 86-92 | 74-81 |

| Surface treatment | Al(OH)3 | Al(OH)3/ stearic acid |

Al(OH)3 | Al(OH)3 | Al(OH)3/ stearic acid |

ZrO2/ Al(OH)3 |

| OA(g/100g) | 40-47 | 24-30 | 27-34 | 29-38 | 17-24 | 35-45 |

| SSA(m2/g) | 75-85 | 50-60 | 35-45 | 35-45 | 25-35 | 65-85 |

| Particle size(µm) | 0.01-0.03 | 0.01-0.03 | 0.03-0.05 | 0.03-0.05 | 0.03-0.05 | 0.03-0.05 |

| Surface property | hydrophilic | hydrophobic | hydrophilic | hydrophilic | hydrophobic | hydrophilic |

| Typical Applications | Ink・Paint | Ink・Paint | Ink・Paint | Ink・Paint (High weather resistance) |

Ink・Paint | Ink・Paint (High weather resistance) |

| TEM |  |

|

||||

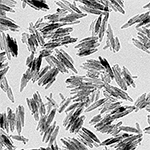

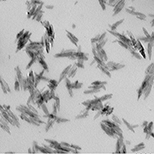

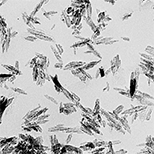

2. Specifications for TTO-S and TTO-V series (wet process)

The TTO-S and TTO-V series are mainly used as raw materials for cosmetics because they have higher transparency and excellent UV-absorption properties.

*You can see the entire image in the figure by scrolling horizontally.

| Grade | TTO-S-3 | TTO-S-4 | MPT-136 | MPT-186 | MPT-187 | TTO-V-3 | TTO-V-4 | TTO-V-5 |

|---|---|---|---|---|---|---|---|---|

| Crystal form | Rutile crystal | |||||||

| TiO2(%) | 80-87 | 78-84 | 71-77 | 80-86 | 82-88 | 80-90 | 68-74 | 79-87 |

| Surface treatment type | Al(OH)3 | Al(OH)3/ stearic acid |

Al(OH)3/ stearic acid |

Al(OH)3/ stearic acid |

Al(OH)3 | Al(OH)3 | Al(OH)3/ stearic acid |

Al(OH)3 |

| OA(g/100g) | 52-62 | 19-39 | 21-25 | 26-36 | 55-65 | 40-60 | 25-35 | 49-59 |

| SSA (m2/g) | 85-105 | 52-72 | 40-60 | 50-66 | 80-110 | 120-150 | 60-80 | 100-130 |

| Particle size (µm) | Width: 0.01-0.02 Length: 0.05-0.1 |

Width: 0.01-0.02 Length: 0.05-0.1 |

Width: 0.01-0.02 Length: 0.05-0.1 |

Width: 0.01-0.02 Length: 0.05-0.1 |

Width: 0.01-0.02 Length: 0.05-0.1 |

Width: 0.005-0.015 Length: 0.03-0.09 |

Width: 0.005-0.015 Length: 0.03-0.09 |

Width: 0.005-0.015 Length: 0.03-0.09 |

| Surface property | Hydrophilic | Hydrophobic | Hydrophobic | Hydrophobic | Hydrophilic | Hydrophilic | Hydrophobic | Hydrophilic |

| TEM |  |

|

|

|||||

3. Neutral Titania Sol “TTO-W-5”

TTO-W-5 is highly transparent and stable aqueous titania sol of rutile type TiO2, treated with silica on the surface.

| Appearance | White liquid |

|---|---|

| Crystal form | Rutile |

| TiO2(%) | ca. 30 |

| Surface treatment | SiO2 |

| pH | 6.0-8.0 |

| Viscosity(mPa・s) | 50 max. |

Transparency of TTO series

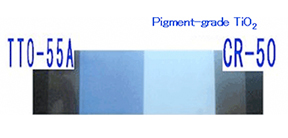

- Ultra-fine TiO2 exhibits higher transparency than pigmental TiO2. (see photo 1)

- To obtain high transparency, the dispersion condition is important in general. The finer particle size are, the stronger dispersion is required.

Click here more information.

Photo.1 Comparison of transparency between TTO and pigmental grade, CR-50.

(The photo on the left compares the transparency of the two TiO2, with paints containing respective TiO2 applied to transparent film, against a black background.)

Paint condition

Resin: Acrylic melamine

PWC: 3.3%

Thickness: 9.9µm

Transparency of coatings using the TTO-55C, TTO-S4, TTO-V4, and

(commercially available) ultrafine zinc oxide

Flip-flop effect

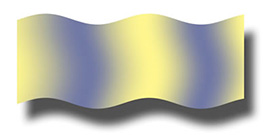

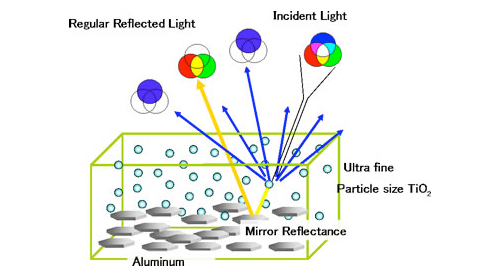

The metallic paint containing ultra-fine TiO2 changes its color from gold to blue by varying the viewing angle. The illustration as below shows the viewing color change by the flip-flop effect.

Click here for more information

Viewing image of flip-flop effect

Shown on the right is a rendered image of a corrugated sheet coated with a metallic paint containing ultrafine titanium dioxide particles and aluminum flakes.The color of the coating is generally pale golden due to the blue light scattering effect of ultrafine titanium dioxide particles, but on curved surfaces, on which the angle of reflection of light locally differs from the angle of incidence, the blue tint is enhanced. The result is a vivid flip-flop effect with which the surface shows gradation from golden yellow to blue.

Characteristics of ultra-fine TiO2 in paint system

![Graph: TiO2 concentration vs. Transmittance [Acrylic/melamine paint]](/eng/products/images/functional02_img12.gif)

1. Influence of concentration

The figure shows transmittance curves when changing the concentration of TTO-55(A) in an acrylic/melamine paint system.

As is clearly seen, when increasing the concentration of TTO, UV-shielding capability is enhanced naturally while transparency for visible light decreases to the contrary. The quality can be improved to some extent by intensifying dispersion in terms of the balance between transparency and UV-shielding capability.

2. Dispersion

The dispersion of ultra-fine TiO2 is much more difficult than that of pigmental TiO2 because ultra-fine TiO2 tends to coagulate more strongly. Therefore, in order to utilize characteristics of ultra-fine TiO2 sufficiently, required dispersion energy is several times stronger than that for pigmental TiO2.

While it is difficult to achieve the dispersion to primary particles, strong dispersion enables ultra-fine TiO2 to suit to automotive metallic coatings or under-layer applications where surface smoothness is important.

2-1. Changes of various properties by intensifying dispersion

Changes of gloss, paint colors, visible and UV transmittance by intensifying dispersion are given in the figure below.

2-1-1. Gloss and surface smoothness

While pigmental TiO2, CR-50, exhibits fairly high gloss and surface smoothness even at weak dispersion, ultra-fine TiO2 shows low gloss at the same dispersion level due to its strong coagulation. However, by intensifying dispersion, ultra-fine TiO2 exhibits higher gloss than pigmental TiO2. This tendency is more remarkable in TTO-51 than TTO-55.

In this way, coatings with excellent surface smoothness can be obtained, which can not be achieved by pigmental TiO2. Development of new applications by utilizing these properties of ultra-fine TiO2 is now under progress.

2-1-2. Visible light transmittance and UV-shielding capability

While the transmittance of pigmental TiO2, CR-50, becomes lower both for visible light(550nm) and UV(350, 300nm) by intensifying dispersion, the transmittance of ultra-fine TiO2, TTO-55(B) and 51(A), becomes higher for visible light and lower for UV.

Manufacturing methods of ultra-fine TiO2

1. Various manufacturing methods

Manufacturing methods of ultra-fine TiO2

Many methods have been proposed for producing ultrafine titanium dioxide. The following manufacturing methods are generally used.

2. ISK's manufacturing process

ISK manufactures ultra-fine TiO2 in the process, shown in the following procedures.

Various grades are manufactured in this process.

Production process of TTO-55 and TTO-51 series

Production process of TTO-S series

Special color effect onto metallic paint (Flip-flop effect)

The metallic paint containing ultra-fine TiO2 gives unique appearance which can not be obtained by conventional metallic paint. The phenomenon of color change in brightness and color of coating, depending on viewing angle, is called flip-flop effect. The effect is often applied for automotive paint.

The most important property required for TiO2 in this application is weatherability, and TTO-55(D) is recommended from this point of view.

Mechanism of flip-flop effect

In the metallic paint containing ultra-fine TiO2, blue portion of the incident light is dominantly scattered due to its small particle size. Consequently, remaining portion of light, i.e. yellow light, is reflected by flaky aluminum.

Thus, scattered light looks like bluish while regular reflection looks like metallic yellow, i.e. gold. So different colors are appeared depending on the viewing angle.

Principle of the Flip-Flop Effect

When incident light hits ultrafine titanium dioxide particles contained in a metallic paint, bluish light is scattered more than other colors due to the smallness of the ultrafine titanium dioxide particles. As a result, green and red light without a bluish color (or yellowish golden light) is specularly reflected by aluminum flakes.

To be more specific, the scattered light has a strong bluish tinge, while the specular reflected light has a strong yellowish tinge (gold), so the hue differs depending on the viewing angle.

Typical result of flip-flop measurement

Followings are the typical results on flip-flop effect of metallic paint containing aluminum powder. When incident light at -45 deg. comes in, Y and b* show maximum values at +45 deg. which means regular reflection. The paint systems with and without TiO2 show almost similar behavior in Y value, while remarkable difference is seen in b* values. The b* value of the system with TiO2 changes significantly in variation of the viewing angle.

Relationship between detective angle and Y value

Relationship between detective angle and b* value