Functional Materials

High Purity Titanium Dioxide, CR-EL/PT Series

The technology of electronics has shown very remarkable progress and electronic devices such as cellular phones and personal computers have become more and more popular. High performance, high accuracy and the miniaturization of those electronic devices have been eagerly required.

ISK has supplied high-purity titanium dioxides as raw materials of ceramic capacitors, noise filters and so on which are used in those electronics devices.

Strengths

-

Strength 1A wide variety of purity and particle size

-

Strength 2Narrow particle size distribution

-

Strength 3We have newly added a line of high-purity and small-particle-size grades for next-generation products.

Typical Applications

- Raw material for dielectric materials (barium titanate, lead zirconium titanate, etc.) used in electronic ceramics such as capacitors, piezoelectric elements, and thermistors

- Raw material for titanium nitride and other non-oxide ceramics used as structural materials

- Raw material for rutile single crystals used for artificial precious stones and optical communication actuators

Properties of High-Purity Titanium Dioxide, CR-EL and PT series

- Various grades depending on purity and particle size.(Click here for Grade List)

- Narrow particle size distribution achieved using pigment synthesis technology

- We have newly added a line of high-purity and small-particle-size grades for next-generation products (PT-401M).

- For general-purpose applications, the PT-501R is suitable.

Grade Classification by Particle Size and Purity

| Particle Size |

Purity of TiO2 | ||

|---|---|---|---|

| 99.99% | 99.9% | 99% | |

| Middle | CR-EL | PT-501R | |

| Small | PT-401MPT-401L | ||

| Very small | PT-601Aunder development | ||

Fig. 1 Relationship between particle size and thermal shrinkage

Thus the purer and smaller grades can be expected to show higher reactivity in the synthesis of complex oxides such as barium titanate.

Grade List

ISK's high-purity titanium dioxide offers exceptionally high purity and stable quality. It is used in a wide range of applications, including electronic ceramics.

Available Particle Sizes and Purity Levels

*You can see the entire image in the figure by scrolling horizontally.

| Particle Size | Crystal Form |

TiO2 (%) |

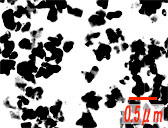

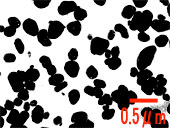

Grade Name | Electron Micrograph |

Remarks |

|---|---|---|---|---|---|

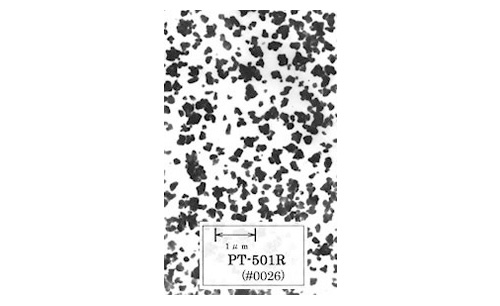

| Middle | Rutile | 99 | PT-501R (0.18µm) |  |

Sulfate Process PT-501R is suitable for conventional applications such as disc capacitors and PTC ceramics. |

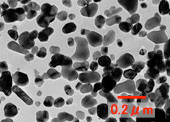

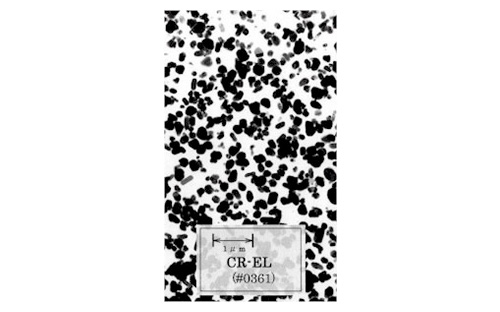

| 99.9 | CR-EL (0.25µm) |  |

Chloride Process

|

||

| Small | Rutile | 99.99 | PT-401L (0.13µm) |

|

Chloride Process

|

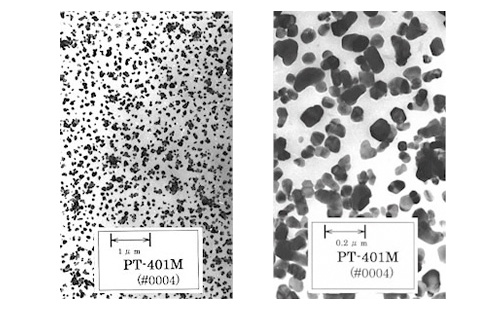

| PT-401M (0.07µm) |  |

||||

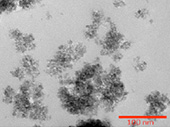

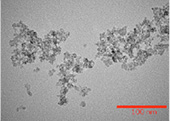

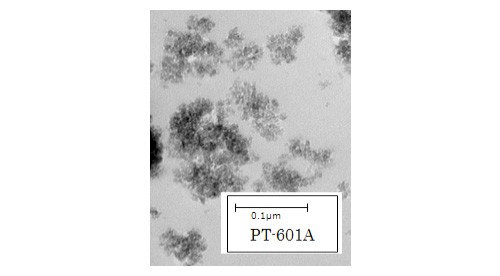

| Very Small | Anatase | 99.9 | PT-601A |  |

Special Hydrolysis PT-601A is a fine titanium dioxide particle for electronic ceramics with anatase form, high purity, and excellent reactivity. |

| Under development |  |

Special Hydrolysis It is a fine titanium dioxide particle for electronic ceramics with anatase form, high purity, and excellent dispersibility in liquid phase. |

CR-EL

CR-EL is ISK's standard grade manufactured by the chloride process.

The particle size of this grade is ca. 0.25µm which is the same size as conventional white pigment.

CR-EL shows excellent dispersibility and reactivity. Moreover, consistency of the quality has been achieved, which has made it suitable for electronic ceramic applications.

Basic physical properties (analysis examples)

| CR-EL | ||

|---|---|---|

| TiO2(%)* | 99.97 | |

| Rutile ratio (%) | 99.1 | |

| Specific surface area (m2/g) | 6.8 | |

| Average particle size (µm) | 0.25 | |

| Impurities (%) | Fe2O3 | 0.0031 |

| Al2O3 | 0.006 | |

| SiO2 | 0.013 | |

| Nb2O5 | 0.000 | |

| Na2O | 0.002 | |

| Moisture (%) | 0.09 | |

| Ignition loss(%) | 0.13 | |

* TiO2(%)=(100-Total impurities(%))

Ignition loss, SO3, Cl and C are not taken into account in the above calculation.

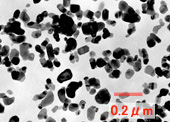

PT-401M

PT-401M is a high-purity titanium dioxide with small particle size, which is manufactured by the chloride process.

This grade shows as excellent dispersibility and reactivity as CR-EL, and it is suitable for electronic ceramic applications which especially require fine particles.

Basic physical properties (analysis examples)

| PT-401M | CR-EL | ||

|---|---|---|---|

| TiO2(%)* | 99.99 | 99.97 | |

| Rutile ratio (%) | 46.7 | 99.1 | |

| Specific surface area (m2/g) | 20.5 | 6.8 | |

| Average particle size (µm) | 0.07 | 0.25 | |

| Impurities (%) | Fe2O3 | 0.0026 | 0.0031 |

| Al2O3 | 0.003 | 0.006 | |

| SiO2 | 0.000 | 0.013 | |

| Nb2O5 | 0.001 | 0.000 | |

| Na2O | 0.001 | 0.002 | |

| Moisture (%) | 0.41 | 0.09 | |

| Ignition loss(%) | 0.65 | 0.13 | |

* TiO2(%)=(100-Total impurities(%))

Ignition loss, SO3, Cl and C are not taken into account in the above calculation.

PT-501R

PT-501R is high-purity titanium dioxide manufactured by the sulfate process.

PT-501R is rutile in the crystal form.

There is suitable for various applications such as ceramic capacitors due to the narrow particle size distribution.

Basic physical properties (analysis examples)

| PT-501R | ||

|---|---|---|

| TiO2(%)* | 99.74 | |

| Rutile ratio (%) | 92.4 | |

| Specific surface area (m2/g) | 8.9 | |

| Average particle size (µm) | 0.18 | |

| Impurities (%) | Fe2O3 | 0.0039 |

| Al2O3 | 0.002 | |

| SiO2 | 0.000 | |

| Nb2O5 | 0.14 | |

| Na2O | 0.001 | |

| Moisture (%) | 0.18 | |

| Ignition loss(%) | 0.31 | |

* TiO2(%)=(100-Total impurities(%))

Ignition loss, SO3, Cl and C are not taken into account in the above calculation.

PT-601A

PT-601A is high-purity titanium dioxide manufactured by special hydrolysis process, and has a high specific surface area more than 300 m²/g on BET method, making it suitable for applications in electronic materials that require high purity and reactivity.

Basic physical properties (analysis examples)

| PT-601A | ||

|---|---|---|

| TiO2(%)* | 99.9 | |

| Crystal form | Anatase | |

| Specific surface area (m2/g) | 343 | |

| Impurities (%) | Fe2O3 | 0.0002 |

| Al2O3 | 0.004 | |

| SiO2 | 0.006 | |

| Nb2O3 | 0.003 | |

| Na2O | 0.00000 | |

| Moisture (%) | 3.48 | |

| Ignition loss(%) | 6.57 | |

* TiO2(%)=(100-Total impurities(%))

Moisture, Ignition loss, SO3, Cl and C are not taken into account in the above calculation.