Business Introduction

Titanium oxide, functional materials, etc.

ISK offers titanium white to make the world brighter

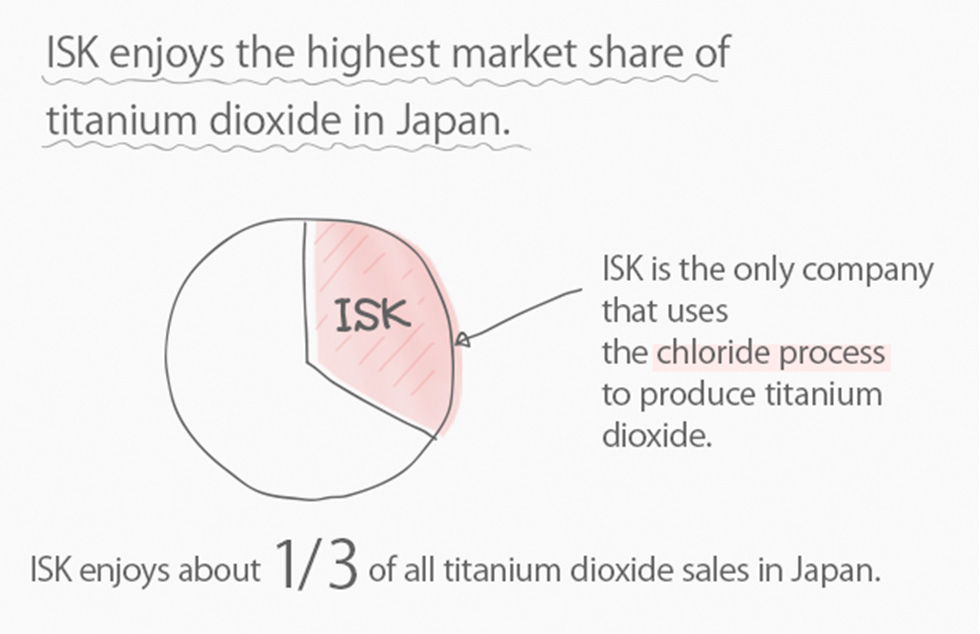

Titanium dioxide is a pigment used for whitening industrial products (paints, plastics, ink, paper, rubber, etc.), cosmetics, synthetic fibers, pharmaceuticals and various other products that are indispensable in our daily lives.

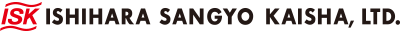

The titanium dioxide production volume of ISK is the largest of any company in Japan (as of April 2025, according to the results of an ISK survey). In addition, ISK is the only company in Japan to produce titanium dioxide with a chloride process* that is friendlier to the environment.

Well known under the trade name of TIPAQUETM, ISK titanium dioxide is highly valued by customers because of its variety of unique characteristics and high quality. As the world’s top brand, this product is expanding its application not only in Japan but also overseas.

※ Titanium dioxide can be produced using either a sulfate process or chloride process. ISK uses both processes. The chloride process reduces industrial waste, although it requires a more sophisticated technique.

*You can see the entire image in the figure by scrolling horizontally.

Due to various functions, titanium dioxide expands its usability.

Besides its use as a white pigment, titanium dioxide exhibits various functions to create value that makes our lives more comfortable. An example is ultrafine particle size titanium dioxide which is produced by reducing the particle size to about one-tenth that of titanium dioxide used as a white pigment. The ultrafine particle size titanium dioxide has a variety of applications, including an UV radiation shielding ingredient, flip-flop paints (that display different colors depending on the angle of vision), and an additive agent for copier toners.

Further, electro-conductive titanium dioxides, which are produced by combining with an electro-conductive tin oxide, are physically and chemically stable, and superior in chemical resistance and heat resistance. Because of their easy-to-color property, these types of titanium dioxides are used for various kinds of paints, inks, fibers, and many other products as an antistatic material. In particular, the acicular electro-conductive titanium dioxide ISK developed using its proprietary technology is attracting customers’ attention as a unique product that makes a material antistatic even when only a small amount is added.

High purity titanium dioxide is another type of titanium dioxide that exhibits a great variety of inherent characteristics.

High purity titanium dioxide is the principal raw material of electronic ceramics that are used in televisions, personal computers, smartphones, and other electronic devices. Furthermore, because of its stable quality, high purity titanium dioxide is also used as a raw material of barium titanate, which is used for electronic ceramic capacitors (a component that stores electricity when a voltage is applied).

Products

Keeping our living environment clean.

Photocatalytic titanium dioxide: A product that is expected to clean the environment by decomposing organic substances and providing equipment with a self-cleaning function.

Photocatalytic titanium dioxide reacts with sunlight (ultraviolet rays) and exhibits a strong organic decomposition power. Thus, this product is expected to achieve deodorization, antibacterial, antifouling, environmental cleanup (air, water, and soil), and various other effects. When coated over window panes, walls of buildings, tents, and the outer surfaces of other structures, photocatalytic titanium dioxide makes them hydrophilic (because of its super-hydrophilic property). As a result, these structures are provided with a self-cleaning function and protect themselves from dirt and pollution by only being exposed to sunlight and rainwater.

ISK has developed a unique technology called Photocatalytic Coating – CLEAN NANO KOHOTM. Using this technique, ISK adds antifouling and antifogging properties to glass panels located outdoors.

Titanium dioxide for catalytic use: A product that plays a role in the prevention of air pollution.

Titanium dioxide for catalytic use has a large specific surface area, and is used widely as a carrier of denitrification catalyst to eliminate nitrogen oxides (causative substances for photochemical smog) discharged from thermal power plants, refuse incinerators, automobiles, and various other equipment.

Products

Heat shield pigments for heat mitigation.

In Japan, summer heat has become too intense to be felt safe. What people can do is not to counter nature, but to explore better ways to live in their given environment. One possible way is to coat steel sheets with a paint formulated to reflect the heat-producing infrared wavelengths of solar radiation for reduced heat.

ISK has developed a heat shield pigment as a key ingredient of heat shield paints. This pigment comes with superb specs in terms of thermal insulation performance, durability, environmental friendliness, and toning performance critical for color production of the paint.

TIPAQUE BLACK is a family of black pigments. Compared with existing pigments, they have a higher jet-black level and are easier to work out a color design. Being chromium-free, the products are highly eco-friendly.

We have also launched products with improved resistance to acid rain, especially popular for use on pre-coated metal (PCM) sheets.

Our product line also includes a heat shield coating agent for window panes, which achieves a visible light transmittance of at least 80%. Our sales channel will expand to enable this coating agent to be used for greenhouse applications in addition to traditional office building uses.

Products

Reduced physical barriers to the use of matte paint and improved design appeal.

When matted, some products make their distinctive presence felt even more.

However, matte paint has been considered difficult to use for enhanced design appeal because of its disadvantages in terms of weatherability and retention of the paint film.

Matting agent products produced through our titanium oxide manufacturing technology improve these disadvantageous conditions.

These products materialize the philosophy of your flagship model requiring the high quality texture that the product designer had in mind, in a wide range of colors. They can also express a smooth feel, resulting in a pleasant surface texture as well as a great look, thereby augmenting the value of your product.

Dark color options are also available in addition to white paint. With its paint technology, ISK strives for high customer satisfaction.

Products

By-products derived from titanium dioxide production process are playing an important role in environmental preservation.

Calcium sulfate and iron oxide: By-products derived from the titanium dioxide production process.

In addition to being used as the raw materials of gypsum wallboards and cement, these by-products are powdered extremely fine by ISK’s proprietary technique and are put on the market as environmental products.

GypsanderTM, a soil improvement additive containing calcined gypsum as the major ingredient, hardens soft soil until it becomes nearly as hard as natural soil.

Fix-AllTM, a heavy metal insolubilization material containing iron oxide and calcium sulfate as major ingredients, adsorbs heavy metals contained in waste water and prevents these metals from leaking out of contaminated soil.

MT-V3TM, a volatile organic compound (VOC) decomposition material containing iron oxide and iron powder as major ingredients, removes trichloroethylene and other VOCs from contaminated soil and water.

ISK has the advantage of combining these products to make the most of all of their functions. In particular, ISK is working to solve contaminated soil-specific problems by insolubilizing heavy metals while improving the softness of the soil.