Occupational Safety and Health

Basic Policy

ISK’s safety and health policy is to ensure the safety, security, and health of employees and local residents by complying with safety and health-related laws, preventing accidents and disasters, building a pleasant work environment, and constantly raising the level of safety and health. Additionally, we have established “occupational safety and health, operation safety, and disaster prevention” as one of our Group’s key issues (materiality) and are promoting initiatives aimed at achieving a lost injury frequency rate and severity rate of zero.

Safety and Health Management Structures

In line with our "Basic Policy on the Environment, Safety and Health," we have established the Environment, Safety & Health Management Committee under the purview of the Office of President to deliberate on the highest level policy proposals relating to safety and health, the environment and chemical substance management. Below this is the Environmental, Safety & Health Council which promotes environmental conservation, thorough chemical substance management, occupational safety and health, and health promotion. Additionally, compliance with regulations regarding the environment, safety, and chemical substance management is audited by the Environmental, Safety & Health Audit Team, which reports its findings to the Environment, Safety & Health Management Committee.

*You can see the entire image in the figure by scrolling horizontally.

Safety and Health Management System

At ISK, we have established "environmental, safety and health goals" which reflect the characteristics of operation at each business location, and, in order to achieve these goals, key initiatives are set at the beginning of each fiscal year.

At the end of each fiscal year, the progress of activities related to the key initiatives is reviewed by each department and the plant as a whole. After compiling these activities, they are reported to the Environmental, Safety & Health Council, where information is shared and issues are sorted out. These issues are then escalated to the Environment, Safety & Health Management Committee for deliberation.

After reflecting on the initiatives of the current fiscal year, the Environment, Safety & Health Management Committee sets goals for the next fiscal year, and new initiatives are planned at each business location; thus a PDCA cycle is implemented to foster an upward spiral in occupational safety and health and health promotion awareness.

Occupational Safety and Health Initiatives

“CNRIA” wearable device for preventing heatstroke

“CNRIA” wearable device for preventing heatstrokeHeatstroke Prevention

As the heatwaves become more intense, we are taking basic steps to prevent heatstroke, such as by improving the working environment, managing the physical condition of workers, and managing working hours. In order to ensure product quality, some work is done indoors, which may result in high temperatures and humidity. In order to more effectively prevent heatstroke, we have introduced heatstroke prevention wearable devices* as an additional measure against heatstroke.

*It is worn on the wrist like a watch and prevents heatstroke by detecting an increase in core body temperature (heat buildup) and then sounding an alarm.

Morning calisthenics

Morning calisthenicsDaily Calisthenics

It’s not known exactly when ISK began holding daily calisthenics, but it has for sure been held every day before work since the 1950s. Daily exercise helps prevent injuries and are important in alerting employees to their physical condition on that day. Daily calisthenics are also believed to maintain good health. With average employee age increasing, calisthenics are growing in importance and ISK will continue to hold them in earnest.

Technological Advancement-driven Efforts to Enhance Safety

We are utilizing drones (unmanned aerial vehicles) equipped with high-magnification zoom cameras to improve the efficiency and accuracy of inspections in high-altitude locations. This results in a reduction in the need for scaffolding and work at heights, leading to lower costs and a reduced risk of workplace accidents. Furthermore, by incorporating a 3D scanner, we can now create highly accurate 3D models of structures, including piping systems, and this data can be managed on the cloud. This allows us to obtain information about facilities and equipment without having to rely on blueprints or on-site inspections.

In addition, we have implemented digital X-ray (DR) technology for non-destructive testing in some areas, which has led to improved inspection accuracy and reduced inspection time. Through these advanced technological initiatives, we aim to enhance maintenance and safety management via predictive maintenance.

Safety and Accident Prevention Initiatives

A safety patrol

A safety patrolSafety control is the foundation of ISK’s business. At the Yokkaichi Plant, our target is to eliminate fires, explosions, and any kinds of leaks. We conduct risk assessments with What-If Scenario Analysis: when installing new equipment or upgrading existing ones, when updating production methods, and when doing safety assessments of existing equipment where high-risk items such as hazardous substances and high-pressure gas are handled.

Then, countermeasures are taken for the extracted potential risks. We also focus on accident case study education, and company executives conduct periodic safety patrols.

Earthquake and tsunami evacuation drills to prepare for a megathrust earthquake are held annually for all personnel and vehicles using the Yokkaichi Plant. This improves our ability to respond quickly and appropriately to such emergencies.

Practice hanging by a safety belt

Practice hanging by a safety beltHazard Simulation Classes for New Employees and Mid-Career Hires

In 2019, we added hands-on training to our classroom-centered health and safety training for new employees and mid-career hires. Using model equipment so employees can experience risks such as being exposed to liquids when operating valves, the training gives all participants firsthand experience in on-site dangers.

ISK also sends groups of employees to take danger simulation seminars at outside training facilities, where they do things like practice hanging in mid-air with safety belts and experience a simulated accident of getting pinched by or caught in equipment. This heightens their awareness of precaution and teaches them to avoid dangers in their actual work.

Safety and Disaster Preparedness Initiatives

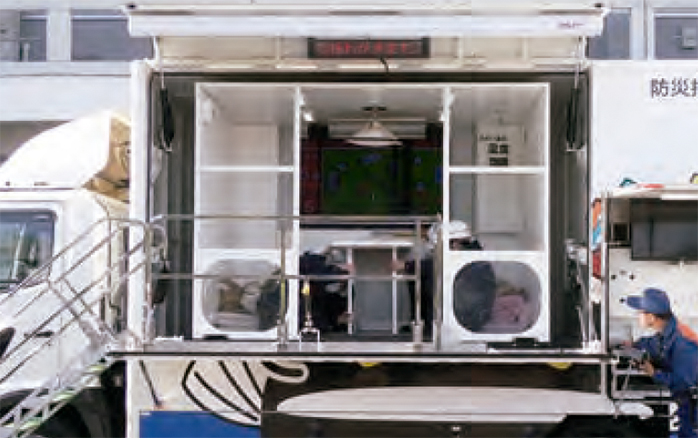

Joint drill by ISK’s Self Disaster Team and the local fire department

Joint drill by ISK’s Self Disaster Team and the local fire departmentYokkaichi Plant

In preparation for emergencies, Yokkaichi Plant conducts annual joint drills with the plant’s Self Disaster Team and the local fire department, which are open to the local residents.

In fiscal 2020 and 2021, due to the impact of COVID-19, we cancelled the joint training with the fire department and the public was, and conducted emergency drills in-house only. But in fiscal 2022, for the first time in three years, we restarted joint drills with the local fire department. We work to improve our level of disaster preparedness each year by adding new elements (such as the use of drones) to the drills.

Initial fire extinguishing training in the laboratory

Initial fire extinguishing training in the laboratoryCentral Research Institute

We conduct comprehensive disaster drills each year that involve all employees in order to foster better individual disaster prevention awareness. In October 2024, under the supervision of fire department personnel, a series of drills simulating a fire outbreak in the Formulation Research Laboratory was conducted involving all departments (from the outbreak of a fire to getting people in the vicinity involved, alerting others, initial firefighting, calling emergency services, reporting to superiors, evacuation, and safety confirmation). After all staff gathered, firefighting training was conducted using water extinguishers under the guidance of firefighters.