Functional Materials

Electro-conductive Materials ET/FT/SN/FS Series

ISK’s electro-conductive materials use tin oxide as a major component. In addition to high electro-conductivity, these materials exhibit superb absorption of near infrared rays (heat rays).

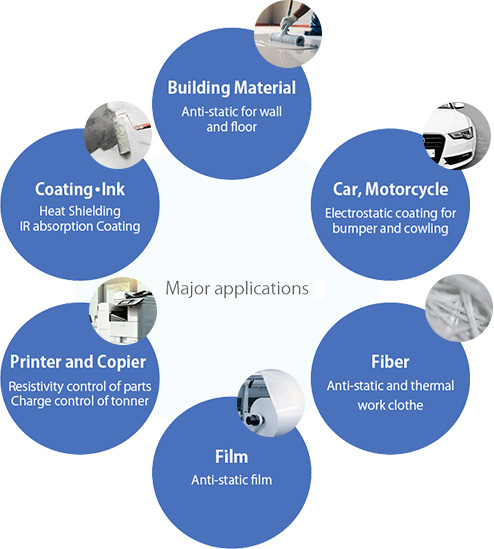

Their major applications include floor paints for clean rooms which are sensitive to dust and static electricity and conductive paints that enable electrostatic painting of automotive plastic bumpers.

Grades are available in four series: white electro-conductive titanium dioxide (ET series), acicular white electro-conductive titanium dioxide (FT series), transparent electro-conductive materials (SN series), and acicular transparent electro-conductive materials (FS series).

Strengths

-

Strength 1White or transparent antistatic materials can be achieved

-

Strength 2A rich variety of products differing in particle size and shape

-

Strength 3Employed in a wide range of applications

Typical Applications

- Conductive primer for electrostatic coating

- Antistatic coating (building materials, floors, and films)

- Antistatic ink

- Antistatic resin and fiber and heat-shielding paint (films)

- Thermal fiber

Application

Electro-conductive primer for electrostatic coating

An electrostatic coating on a plastic bumper needs an electro-conductive primer.

Even though a grey electro-conductive primer with carbon black is usually applied as an electro-conductive primer, a white electro-conductive primer with our white electro-conductive titanium dioxide works better for making a thinner white base coat film with enough opacity.

Anti-static coating (building materials and floors)

Example:

PCM coating, floor coating

Properties:

Excellent storage stability, chemical resistance, low humidity dependence, and color matching.

IR-shielding ability of SN-100P

Bellow graph shows transmittance curve of SN-100P coating.

Infrared rays are absorbed due to the plasmon absorption of free electrons of SN-100P.

White electro-conductive materials:ET series(spherical type)

*You can see the entire image in the figure by scrolling horizontally.

| ET-300W | ET-500W | |

|---|---|---|

| Composition | TiO2,SnO2(Sb doped) | |

| Crystal form of TiO2 | rutile | |

| Particle size(µm) | 0.03~0.06 | 0.2~0.3 |

| Powder resistivity1))(Ω・cm) | 10~30 | 2~5 |

| Specific gravity | 5.0 | 4.6 |

| Specific surface area2)(㎡/g) | 25~35 | 6~8 |

| Oil absorption(g/100g) | 25~35 | 15~20 |

| Powder color : L value | 70~80 | 84~88 |

1)9.8MPa compressed powder 2)BET method

White electro-conductive materials:FT series(acicular type)

*You can see the entire image in the figure by scrolling horizontally.

| FT-1000 | FT-2000 | FT-3000 | FT-4000 | |

|---|---|---|---|---|

| Composition | TiO2,SnO2(Sb doped) | |||

| Crystal form of TiO2 | rutile | |||

| Particle size(µm) |

L 1.68 D 0.13 |

L 2.86 D 0.21 |

L 5.15 D 0.27 |

L 9.72 D 0.51 |

| Powder resistivity1)(Ω・cm) | 2~10 | 2~10 | 10~60 | 2~20 |

| Specific gravity | 4.4 | 4.4 | 4.4 | 4.4 |

| Specific surface area2)(㎡/g) | 12~18 | 10~16 | 2~8 | 5~9 |

| Oil absorption(g/100g) | 45~65 | 45~65 | 50~70 | 35~55 |

|

Color in linseed oil ; L value3) |

77 | 77 | 85 | 75 |

1)9.8MPa compressed powder 2)BET method 3)Measurement example

Transparent electro-conductive materials:SN series(spherical type)

| SN-100P | |

|---|---|

| Composition | SnO2(Sb doped) |

| Particle size(µm) | 0.01~0.031) |

| Powder resistivity2)(Ω・cm) | 1~5 |

| Specific surface area3)(㎡/g) | 65~80 |

| Specific gravity | 6.6 |

| Refractive index | 2.0 |

1)Primary particle size 2)9.8MPa compressed powder 3)BET method

Transparent electro-conductive materials:FS series(acicular type)

| FS-10P | |

|---|---|

| Composition | SnO2(Sb doped) |

| Particle size(µm) |

L 0.2~2.0 D 0.01~0.02 |

| Powder resistivity1)(Ω・cm) | ~100 |

| Specific surface area2)(㎡/g) | 25~35 |

| Specific gravity | 6.6 |

| Refractive index | 2.0 |

1)9.8MPa compressed powder 2)BET method